ICE PRESS

LINE Graypants

DISCIPLINE product design

YEAR 2013

ROLE ideation, concept development, prototyping, design for manufacturing, aesthetics and CMF, project management

TOOLS sketching, Rhino 3D, Adobe Illustrator, CNC metal fabrication

MATERIALS aluminum (machined, anodized), stainless steel (turned, polished, pressed)

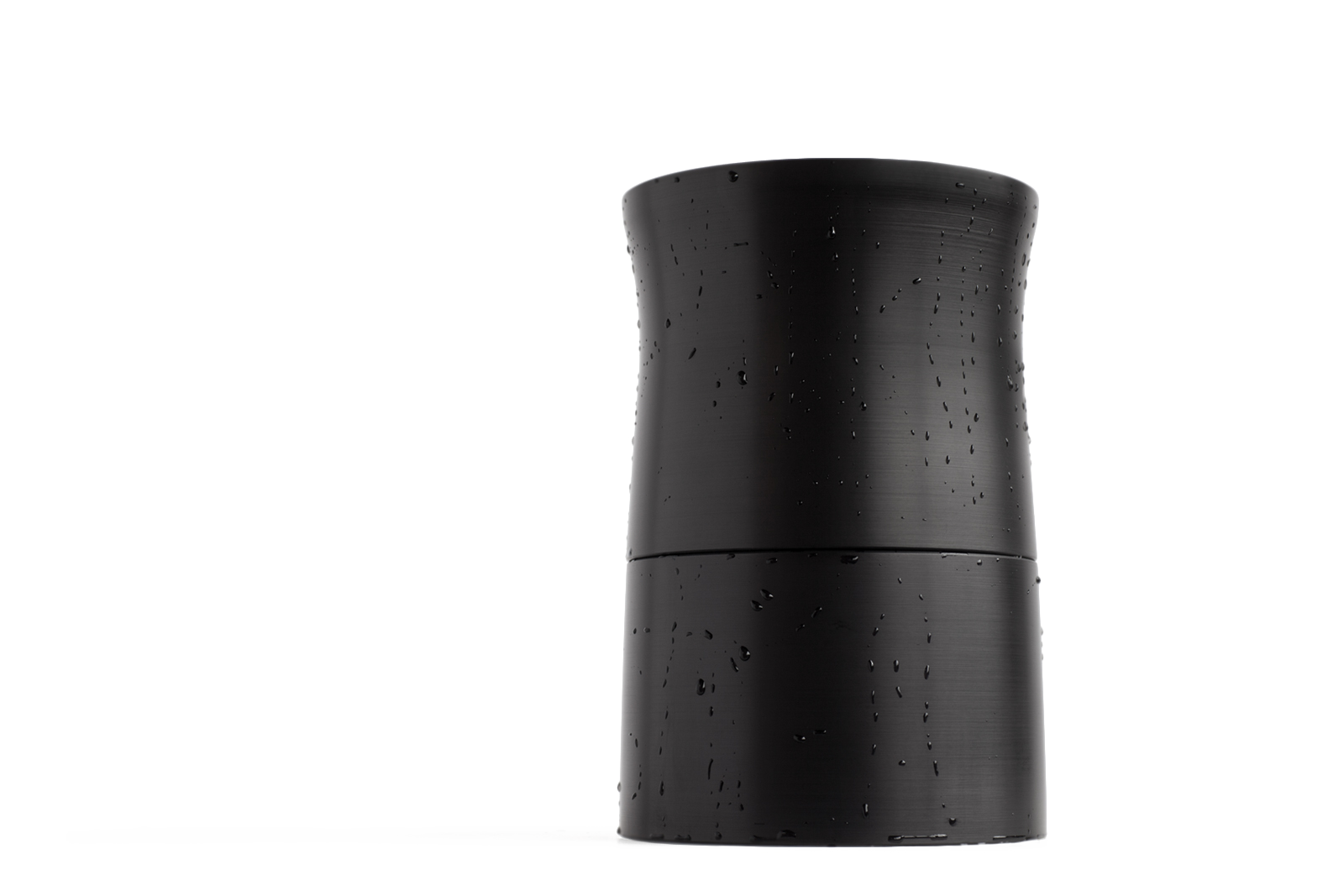

The Ice Press, created for the Graypants product line, is an object designed to shape one's cocktail experience.

Utilizing the thermal properties of aluminum, the Ice Press quickly turns a block of ice into a perfect sphere. The round ice melts slowly, chilling a cocktail without diluting it.

ANALYSIS

This design phase was preceded by thorough market research. Inventorying existing products and identifying details that could be improved upon created the framework for this project. Existing models were basic cylinders, colored to look like copper, featuring bolt-on handles and complicated mechanisms. It was decided that a better ice press needed to be simple in appearance and function.

OBJECTIVES

Develop an aesthetic that simplified the form and was true to its material properties.

Incorporate design details that would improve the function of the press while reducing cost.

Create a better flowing user experience that was more enjoyable to use.

CONCEPT

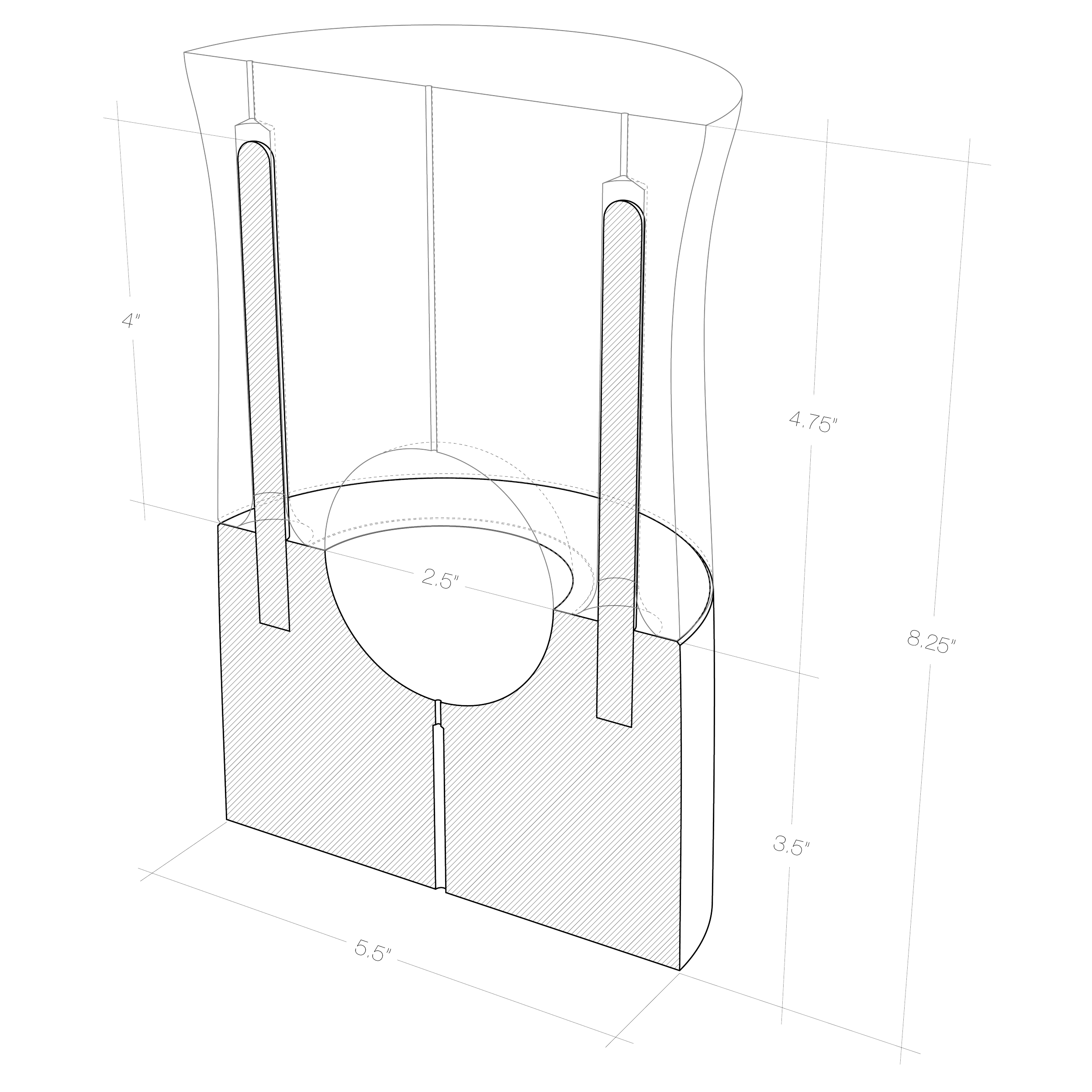

As a countertop object, it was important that the owner be proud to display this product in their home. The form needed to be welcoming and interest people before they ever learned its function. Designing an incorporated handle simplified the aesthetic and eliminated a manufacturing step. Machine time was better used if it went towards improving the performance and usability. This was achieved by routing channels that managed the water from melting ice and machining features that physically guided the user through the process.

The Ice Press is an intricately detailed object.

From the channels that move water to the seamless void that creates the sphere, the Ice Press relies on high-tech machining processes to achieve such tolerances.

The Ice Press is manufactured in Seattle, less than ten miles from where it was designed.

RESULTS

Beauty was achieved by being honest about the materials, finishing the aluminum in a way that celebrated its character instead of attempting to mimic a different metal. Creating a graceful profile softened the industrial feel of the aluminum and served as a grip which eliminated the need for a bolt-on handle and reduced visual clutter.

The grip was formed by utilizing a machining step that was already fundamentally part of the manufacturing process. This eliminated additional hardware and assembly. Designing a process that required fewer steps, but maximized each one, was key to producing this design at a minimal cost.

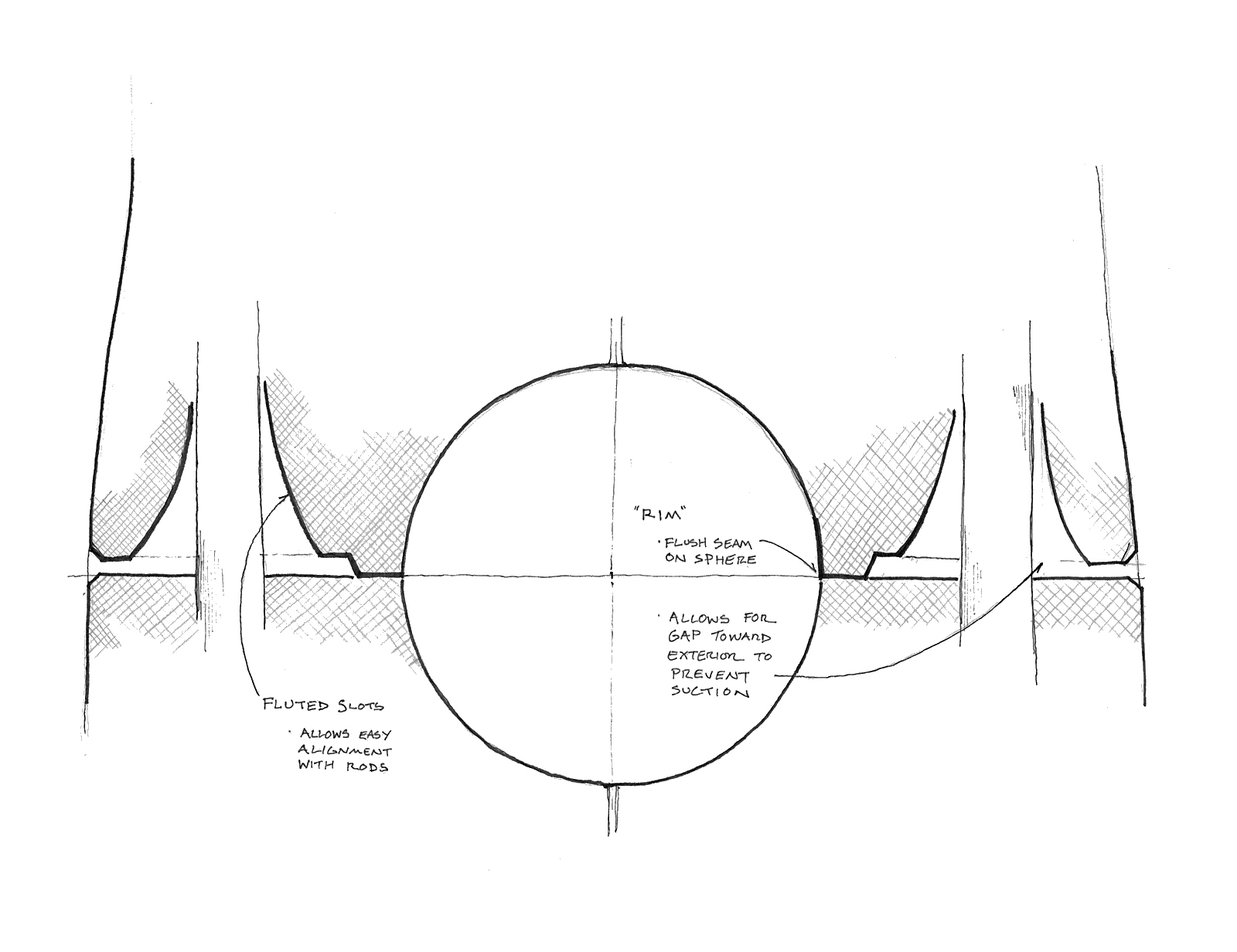

The tapered profile made it intuitive for one to lift the top with two hands. The trumpeted slots made guiding the top onto the stainless steel rods a natural process. Machined details on the two surfaces that came into contact eliminated the suction created by water, allowing the press to be opened easily every time.